Snow Camo

-

Content Count

462 -

Joined

-

Last visited

Posts posted by Snow Camo

-

-

Welcome to an awesome site! 🍻

-

70mph winds yesterday evening. It was raining sideways. Was a good watch on the porch. We like to watch storms lol.

-

3

3

-

-

7 hours ago, Fishfiles said:Yessir! These guys don't get the credit they deserve. Talent

-

1

1

-

-

-

1

1

-

-

Fish

in General Chat

On 2/26/2023 at 10:13 PM, LedFTed said:be hard to get any fishing done.

I'd be fishing Allright....

-

-

Welcome from Texas!

-

Welcome to greener grass 😆

-

Engine Coolant Temp (ECT) Sensor (37870-HN8-A61)

- Intake Air Temperature (IAT) Sensor (37880-MCA-003)

I bet just like any other engine one of these is you issue. Likely the IAT (intake air temp) sensor. Idk but these are in the loop that control fuel.

-

1

1

-

-

Welcome from Texas!

-

Welcome to the site! Help is on the way

-

And yes goggle and apple do listen to everything.

Snowden tried to tell us and folks dismissed him... my how the tides have changed, or come to...

-

-

1 minute ago, shadetree said:if you happen to have at least 1/32 under the bearing ?..then yes..that enough room for the bread to get under it. but when you have a open inner bearing ?, it seems to me it wont work.

No space flush fit

-

4 minutes ago, shadetree said:answer me this, how are you going to get the bread..or whatever you use ?, down under the bearing from the start ?, if there is no room under the bearing, i do not see how you can get anything under it to push this bearing out. this bearing sits down flush inside the case, as in..flat down inside, no space under the bearing. if there was a space under the bearing ?, then yeah..this might work, but seeing how the bearing is all the way down inside the case, i do not see it working..but hey..what do i know ?..i'm just a home school'ed mechanic !..lol.

I had the same thinking. I just knew it sounded stupid because there was no room for the bread to get under the bearing. Idk what the science behind it is, but the bread finds a way to smush under the bearing. Once it does. It's nothing but up from there.

-

1 hour ago, _Wilson_™ said:Toilet paper works too.... Just gotta make sure it's wet..... BUT NOT USED! Lol!

Paper towels

soap grease theres a bunch of defrent materials can be used .....

My friend Richard uses TP......said grease was to messy, and you never want anything (especaily petroleum products) on the contact surfaces of a dry clutch....

Charmin 🐻? Lol

I was just amazed at how easy the process was and watching the bearings lift was puzzling lol

-

1

1

-

-

5 hours ago, _Wilson_™ said:Yup..... Done that myself ..... Works great for pushing out a flywheel pilot bearing.... Among others, that's a great old school problem solver.

When someone told me that trick I was all man whatever. Till I tried it.

It's the best thing since sliced bread🤣😂😂

-

1

1

-

-

6 minutes ago, shadetree said:you gonna work for free ?..if so..we'll barter our advice for your ac work..lol.

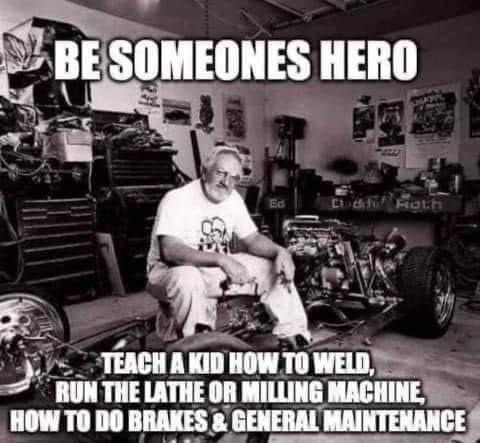

Ya man. I'm Ole school. Each one teach one. Do unto others and so on. Heck I sorta pay due respect and whatnot know what I'm talkin bout? 🙂

-

1

1

-

-

15 minutes ago, AKATV said:Shade

I know it sounds a bit hokey but it works, an old timer showed me years ago

Get a couple slices of bread-fresh lol, if its stale you can dampen it a bit,stuff it down in the bearing hole and find a bolt or shaft that will fit the

hole closely and just keep packing it in there, pretty soon it will get full and as you tap it down with a hammer to keep packing it in it will force the bearing out, you dont have to tap too hard just enough to keep packing it in

Then when it comes out you can just pull out the bread with a pick etc from the hole

First time i did it I was amazed, love the old time ingenuity of it

Let me know how it works for you, might want to support rear of the bearing (opposite side) with wooden block etc

This works like a charm. I do this when replacing bearings in my rc car motors. Easy money

-

Yessir. I been brazing 13 years and soft solderin about the same. That's a cake walk. I am an hvac tech so it's all by trade.

Side note if anyone needs any hvac related help I could likely guide in the right direction, given the right info on the situation.

-

1

1

-

-

I'll get it right soon enough. I'm good with torches, so I'll get the stick down soon enough 😆

-

Oh hey guys good news! Since making the grab bar the weather warmed up a bit and I got to run the quad more then a few mins. That smoke was just moisture from old 108 octane I have left over. I notice moisture building on the grab bar when it was folded down partially blocking the exhaust outlet of the muffler. I lifted the bar out of the way and let the engine heat up and no more white smoke from moisture! I'll still get that compression tester as I would like to see what the engine health really is.

That said I am getting some kibble white valve seals and gaskets after I chip in here in a few weeks. That should stop the oil on the spark plug issue.

-

12 minutes ago, shadetree said:yeah..with mig..you do need gas for stainless steel. i don't see much stainless steel with atv's from the factory ?..lol. so i use my mig with flux core.

got this welder due to needing to weld new stainless bolts on a big stainless humidifier tank at work. That was easy even though I apparently have been using this the incorrect way.

Since I've always wanted to learn I took that opportunity to bring it home and learn on my own. Though the welds on the quad look bad I smooth them out to look good 🤣

-

You know the crazy thing is. I went back to the shop I got the welder from and told them hey I can't weld with this thing. They were like stick welders don't make pretty nice looking wells welds. I was like really, then went and looked up vids and found that to not be true.

Fish is the first person I met who actually got me headed in the right direction. Thanks dude

I have used the rental welder at home depot. I was about to get the mig tig version of this one but that shop said I would need gas to weld stainless.

I'll keep Practicing on making it look better. Getting the correct pool and penitration isn't hard now.

SkullCandy 87 200sx

in Custom Builds - Restorations

Posted · Edited by Snow Camo

Funny🤣 I've still been practicing my welding. Far from being a pro, but I'll get it looking like one eventually.

The correct plexiglass came in today. I like the contrast this one has over the red