-

Content Count

827 -

Joined

-

Last visited

Posts posted by oh400ex

-

-

Welcome!

-

6 minutes ago, TrxPipUK said:Yes I am confused about it as well...

Reading that article and surely if it was 180 out then it wouldn't run? Will it be okay running like this or will I have to go back into the engine and and sort it out properly?

I can't see how it would be like this though.

I remember when setting the timing I thought it looked all backwards when turning it over, but I had the timing spot on so I went with it.

Can I just run it like is?

Are you possibly turning the motor backwards?

Does it turn the same direction when moving the motor with the kicker instead of the ratchet?

Dunno if that would produce what you are seeing...

Edit: If there was a serious problem it would not run. It is either not susceptible to the "180 out" or timed correctly.

-

1

1

-

-

50 minutes ago, TrxPipUK said:Just looking at the valves to check the clearances again seeing as I had the carb off.

And looking at it whilst turning the engine over by hand it seems as though the compression stroke is straight after the exhaust valves shut... this doesn't seem right? I've got the spark plug in as well so I know when the compression stroke definitely is.

Does anyone have an explanation as to why it's like this? Would the valves be set right as long as it's on the compression stroke?

Funny thing is that it runs so surely everything is fine? Lol

Generally confused a bit but think you may have it timed at "180 out"

Honestly... it may not even matter. I never personally do anything but time on the compression stroke...

This article may help clarify a few things... took a few of the highpoints but feel free to give it a closer look

Edit: Confused after watching the video... not sure what I'm missing but something...

QuoteAm I 180 out?

People ask this a lot when they have trouble getting an engine running after they’ve set the cam timing up, or when they bring the piston up to Top Dead Center and find both valves open. This is the common mistake we mentioned earlier, and it's one of the things that's more easily understood when you have a good grasp of the complete cycle. It’s more of a car thing, but if you have an old classic four-stroke from the ‘70’s or before that uses cam driven breaker points, it’s sometimes possible. These days, the answer is usually, “no.” The old way of connecting the ignition to the engine mechanically, that of using a distributor or some other device driven at half speed by the cam, allows a mistake in assembly to be made. A mechanic could position the engine at TDC, and if not careful to check, he could position the ignition trigger to fire during the exhaust stroke instead of the compression stroke. This was referred to as being “180 degrees out” because the distributor or point plate was 180 degrees away from the correct position on the camshaft because of this. Actually, going by the crank, the ignition timing was 360 degrees out.

But with the ignition trigger located on the crankshaft instead, as is the case with virtually all modern single cylinder dirt bike 4 strokes, that’s not possible. Without the cams connected to the crank, one TDC is exactly like another; the rod’s at the top, and the spark signal is given as the crank gets there, every time. So, the only thing that determines which stroke is which is the camshaft(s), and how they are positioned by the assembler. That’s why the service manuals for such engines make no mention of checking for which of the two different TDC’s is used. In operation, there is a second, "wasted" spark that happens near the end of the exhaust stroke.

-

2

2

-

-

5 hours ago, TrxPipUK said:When you say a vacuum leak, where might that be? In the engine?

And lastly, what is the throttle slide diaphragm? I haven't come across it before.

Vacuum (in this context) is referring to the negative pressure generated by the intake of the engine.

It is used on some bikes to assist with throttle response and return. Can leak from the intake tube, carb, etc causing similar issues.

As Goober and Shade mentioned above the TRX300 (and most older racing models) have the rubber diaphragm style slide.

Many different slide styles... I was wrongly thinking you were working on the 300 style carb.

Great advice from Goober to get you fully straightened out above... you got it!

4 hours ago, shadetree said:these dont have that carb set up with the diaphragm..haven't we had this talk before ?..lol.

I think so... 😂

Might have been discussing the 350x (which shares a ton of engine parts with this bike BTW Pip)

-

1

1

-

-

Always tough to tell from a video but the motor sounds great!

Few things stand out to me...

Battery sooner than later... the stator is working overtime... "failure to discharge" was the term the forum came up with I believe.

Idle seems low. More of a preference but too low can more easily show the instabilities.

There may be a vacuum leak somewhere... heard a bit of delay in increase and decrease of RPM.

Tiny holes in the throttle slide diaphragm would be my first suspect if something else doesn't stand out.

-

2

2

-

1

1

-

-

-

I've got pretty limited experience with newer machines compared to old stuff but I love power steering for someone who is getting older.

It makes maneuvering the bike significantly easier and for someone who is aging. If you are concerned about fatigue... go for the EPS. I personally have only seen one unit with a failure and have serviced many. Like the others I would avoid ES and Hondamatic like the coof.

-

1

1

-

-

-

2 hours ago, Chevymec said:I found the 2021 Rancher...

I'd stay away and get a great condition used 500 Foreman FS.

It would be half price of a new rancher and 10x the bike IMO. Buying that late of a model you are always paying the "new tax"

Save 3-4k and get used then get him every accessory he ever wanted.

-

4 hours ago, TrxPipUK said:Okay brilliant, thanks!

So then at TDC use the feeler gauge between the top of the valve stem and tappet and adjust as necessary. Right?

Thanks once again for the help!

Yes exactly!

1 hour ago, TrxPipUK said:So just looking at the valves and the intake is a bit loose at just over 0.13mm, however the exhaust has no clearance at all and is too tight.

The manual says the clearance for both intake and exhaust should be 0.08mm, so I'll set both to that.

Sounds great!

I have had mixed personal results using the feeler gauge method.

It is a very reliable method but for whatever reason I can not get them to sound perfect sometimes with gauges.

I use the gauges but rely more on "feeling" now

When you wiggle the rocker you can feel difference in the size of the gap based on the amount of impact

(If the gap is wider the feeling and sound when wiggling will be different that when the gap is closed too much)

Also would recommend starting the bike and listening before full reassembly if possible.

Just a bit loose is not big deal but a bit too tight would potentially damage the valve seat

Thank you for sharing!

-

2

2

-

-

On 12/7/2020 at 2:27 AM, LedFTed said:As one of your guests, you ever heard the song "bony fingers" or a song bout "Peabody's coal mine and the country store". Peabody's, coal mine, was on the WK parkway. going west from Bardstown, though the dividing line seems to be I 65. i think heard that song before, from the Alan Parson's Project. "eye in the sky".

"Hoyt Axton and Ronee Blakley - Bony Fingers" is one of my all time favorites. Think about it all the time.

"John Prine - Paradise" is the other one I think

Came to the thread to post a different one but those are two great tunes. Nice ones Ted!

-

1

1

-

-

33 minutes ago, TrxPipUK said:I need to check the valve clearances. How do I go about doing this? Do I need to get the engine at top dead center for this or what? Any guidance would be awesome!

Yes the engine needs to be at top-dead-center but on the compression stroke. Make sure the mark is perfectly lined up and that the piston is at TDC.

Intake > Compression > Ignition > Exhaust

You can have the piston at the top on the compression stroke or the exhaust stroke just make sure it's on the compression stroke.

Basically... if you saw the intake valve close just before getting TDC... you got it!

If you just saw the exhaust close it would be wrong.

Service manual does explain this fairly well if you would like a more precise explanation.

Good luck with it!

-

3

3

-

-

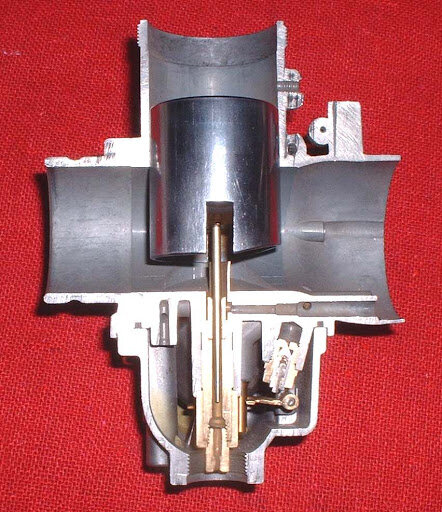

Here is a photo update for y'all.

Frame has been painted with primer to prevent corrosion but will be worked with more later.

Splitting the cases and removing the flywheel went well.

Only follow the method described below if you are discarding the crankshaft and replacing with a new one.

I held the engine up by the flywheel a few inches above a soft surface (in case of drop) and hit the crank with a large ball hammer.

Tapping on the fly lightly helped to loosen a bit and it eventually wiggled out.

With the rest of the bolts under the flywheel removed I again hit the end of the crankshaft to begin forcing the cases apart.

Keeping the gap even as you split is VERY important. The majority of your force in splitting is on the crank but the transmission side needs some persuasion as well.

My favorite method for this is using a soft wooden block and there are always a few points on the cases where it can handle a bit of light impact. Never on a sealing/gasket surface! The force of your hands pulling with light taps to shake things loose is enough most times and is a great starting point.

Sometimes you may need to close the gap on the crank side slightly to encourage the transmission side to let go. It should come off straight ideally and if you see it getting < shaped stop and work the closed side. Never pry it apart... you will ruin the sealing surface or worse.

Once cases are split the crank can be again hit with the ball hammer to remove from that side.

With the part of the transmission that would normally hold the drive sprocket facing up take the top case off leaving the transmission (and likely crank) behind.

The transmission can be disassembled easily and kept as one piece. I will be disassembling this unit to check closely for wear but it usually is not needed. Much easier to keep the transmission gears as one unit. Shift drum and forks will need to come out first and can be put back in easily.

Bearing were removed with heat from propane torch, impact sockets and the ball hammer. Heat the case and try not to heat the bearing.

On this engine, one fell out and one just needed a very light tap.

Lots of new OEM parts have arrived so it's time to get busy!

Thank you for looking!

-

2

2

-

-

3 hours ago, Fishfiles said:Don't remember where I seen it , they make a flexible extension adjuster , looks about 3- 4 inches long and makes adjusting easier , if they have one for a 400X I don't know ( you wrote 400X , I think you mean 400EX ) , Slammed Ranger and OH400EX would know

I've never used one of these adjustable Air/Fuel screws so I can't speak to them personally.

The 400x model is the same as 400ex but newer and with reverse. Off top of my head it was 05 and on that were 400x and everything before was ex

Edit: This is something like the tool that fish is speaking of. I used it on the scooters a bunch but on the 400 I just loosen the carb, adjust and put it back. Don't really adjust very often personally... set and forget.

-

1 hour ago, Fishfiles said:"Legendary" Monkey Video

Yeah that's a San Francisco Turtleneck Guy out of 10 for me on this one.

59 minutes ago, Fishfiles said:Did I ever mention how cool monkeys are ??? Don't think any video could be classified as " Legendary " if there was not at least one monkey in it !!!

I think that's clear so far lol

Just don't like these type of videos... it has 5k dislikes and people screaming "fake" , "setup" and "clickbait" in the comments (rightfully so... it is)

Love animals and think monkeys are awesome just don't like perpetuating these channels that promote violence by setting up fake situations for views.

This particular video was a mix of fake and actual footage of wild animals. Too many jump cuts and "suspenseful" music too lol

Totally unrelated but I stumbled on this video the other day. Great cold open!

~25 seconds

-

1

1

-

-

25 minutes ago, JustWendyNow said:I don't see it for the model years I posted...but oops my bad I guess.

No you're right.

Existing one is for model 2006-2012 and yours is 06-16 (newer)

Don't think there are many differences but always better to have the most updated version!

Even if it was the same manual... I know I'm not alone in appreciating the contribution!

If you like... post an introduction and tell us a bit about what you did with it.

I would guess you have a few other bikes and this is one you fixed for your kid.

Thanks again!

-

2

2

-

-

46 minutes ago, JustWendyNow said:2006-2016 Honda TRX90X Service/Repair Manual

You're welcome! ☺️

2006-2016-Honda-TRX90_Service_Manual_Repair__Trx_90_90ex.pdf 28.49 MB · 0 downloads

Welcome!

Thank you for the contribution!

Balljoints already had this manual in the collection though...

Drill down to Honda > Sport Quads > TRX 90 and you will see the download for the manual.

Sometimes they could be labeled differently but most are there somewhere lol

Edit: 2013 -2016 was missing

-

On 12/7/2020 at 5:23 PM, Fishfiles said:Lynx arguing : maybe some one is making them do it with pulse rays , LOL

The noises they make... my wife said it herself "I make noises like that when I'm mad"

I'd have gotten in trouble if I said it first 😅

---

This video is another legendary moment in motocross history. A bit of explanation...

Chad Reed and James "Bubba" Stewart are two of the most legendary motocross riders of all time. Both are top-of-their-game at this time and an intense rivalry had developed between them. Stewart had heard pre-race talk from Reed saying something along the lines of "If I can get in front of Stewart... I will win"

Stewart took this as a personal challenge and was feeling like his wins were being cheapened by claims that his bike was just faster off the line. The announcers explain the situation pretty well so I'll let them fill in the gaps but he set out to prove that he was faster in every way. Many claim that this is one of the most disrespectful moves in motocross racing history and I think that is at least arguable but trash talking and rivalries are part of racing.This trimmed version is about 2 minutes.

Thank you for looking!

-

2

2

-

-

Fish

in General Chat

10 minutes ago, Fishfiles said:Record bass by hand

https://www.facebook.com/SteveHarvey/videos/2078439662286484

Just wow... was happy to see it go back in at the end! Let em go breed some more big ones lol

-

1

1

-

-

Just a quick little trick to add to the thread...

When installing a battery the screws can be just a tad too short. You end up needing to hold the fastener and it is just a pain.

Take a bit of sticky backed foam and cut a small square. No more nut falling into the bike and getting lost. Some battery brands include these type of fasteners but one sheet of foam can make hundreds.

Thanks for looking!

-

3

3

-

-

Welcome!

-

-

2

2

-

-

4 hours ago, Fishfiles said:a trick he said if you don't have dye is to add some Dawn to the mix , the bubbles not only show where it is going , it helps the product to stick to the leaves

I will co-sign on this trick. Always add just a little bit of dish soap to make it spread better.

You are using the same amount of active ingredient and it works better.

Lots of commercial products include some kind of surfactant as part of the mix. Using the dyed stuff and the respirator is a night-and-day change from my perspective.

Nice work!

-

Just now, sled_22 said:Not worried about sharpening time anymore 🙂

I also bit the bullet a while back and paid $40 bucks (or whatever it was) for the Stihl sharpener.

Like most things it takes a little getting used to and I would rather just bring extra sharp chains with me for a large project but...

If you need to quickly sharpen (and have never been very good with a regular file) this tool makes everything very easy and fast.The machine sharpener doing a batch of chains at once is still my favorite method.

-

1

1

-

1992 350D Starting problems

in Engine - Drivetrain

Posted · Edited by oh400ex

2nd this... have to get lucky with the plug still in

Not from the sound of it...

Whatever rotation the kicker moves the flywheel in is the rotation you should be using.

Turning it backwards with the ratchet explains the confusion.

I'd put it on the proper stroke with mark lined up and readjust the valves.

Edit: I'm getting a bit suspicious of your manual... are you using a Clymer or something lol

Here is an excerpt from my 350x manual (same top end as 350D)

Notice how this is saying counterclockwise rotation on the flywheel

Edit 2:

Factory (86-89) service manual says clockwise. (92 running different bottom end?)

Still not sure what's going on but here is the long/short...

Anti-clockwise is the way that motor turns when running... right? Spin it anti-clockwise

Once the valves are re-adjusted on the compression stroke... run it!

Someone (shade) is going to step in here, see "the blind leading the blind" and shine some light on this situation shortly.