-

Content Count

850 -

Joined

-

Last visited

-

Days Won

3

Posts posted by Melatv

-

-

Hi: Big Welcome Here

-

1

1

-

-

Weather on its way here --

By late Saturday, central and southern sections of New Brunswick will transition to a rain-snow mix, eventually changing over to snow by the evening hours for much of the Maritimes. The mixing across the Maritimes will wrap up by Sunday morning.

Snowfall amounts in the Maritimes will be greatest in northern New Brunswick, which may receive up to 25 cm this weekend. Northern tip of Cape Breton is in line to get 5-15 cm during the same time period.

-

3

3

-

-

They both will work -- so use the Rotella

-

1

1

-

-

-

Hi Fish: Go to setup -- Select tracks -- Track log -- Record -- Show on map

-

1

1

-

-

Hi: Is the battery fully charged?

-

1

1

-

-

Hi: Big Welcome Here

-

1

1

-

-

Hi: Big Welcome Here

-

1

1

-

-

8 hours ago, Fishfiles said:Hire a bunch of Ca'nacks apprentices , sit back drink coffee and mange the place , past them skills on ....

Canuck apprentices they will be replacing your Engineers -- right.

-

2

2

-

1

1

-

-

Hi: Big Welcome Here

-

Hi: Big Welcome Here

-

Are you running the drill in reverse?

-

-

Hi: Big Welcome Here

-

If you are installing heated grips -- you have to watch the wires from the grip doesn't interfere with the thumb throttle

-

-

Hi: Big Welcome Here

-

Fish -- I can't think of anything that would cause that -- other than your finger had moved the screen from the area

-

1

1

-

-

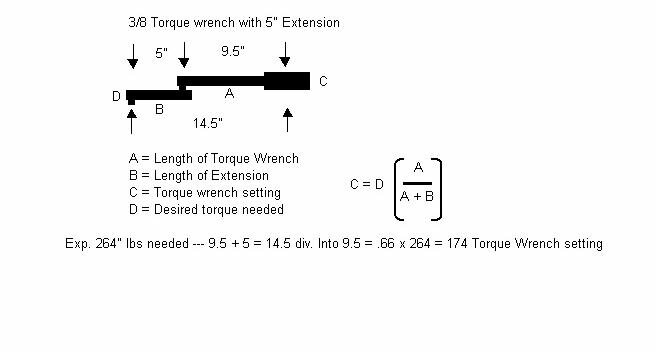

Hi Slowindown:: Here is a way I do it when using a extension straight on to the socket -- I have made some extensions to reach places on ATV's where the Torque Wrench can't be placed. If the Torque is 90 degrees to the extension you don't have use the formula. Use the center of the Torque Wrench handle when using the formula.

-

2

2

-

-

If you torque wrench is straight on like in the (FSM) picture you have to reduce the setting --- but if your torque wrench isn't and is 90 degrees with the tool as the red line you don't have to reduce it --but it's no biggie if left that way -- like Fish has said -- we are not going the the moon

-

2

2

-

1

1

-

-

13 hours ago, slowindown said:Yeah but that’s not what happened in this case. The lock nut wasn’t stuck in one place on the pin. Initially, the lock nut started backing out wit the pin. Then I screwed the pin back in, working it back and forth while using penetrating oil. Pretty rusty. Then the pin started tuning in the lock nut. But when I removed the pin some deeper threads caught the lock nut and backed it out too. So in my mind with all of that movement, the only way to get the torque right was by following the service manual and torquin the pin to 35 inch lbs and then the ring to 87 ft lbs.

Instead of blowing the $39 for the tool I could have bought a cheap socket and cut it with my angle grinder and saved $30 but I decided just to buy the tool

Hi: If you used the locknut tool with your torque wrench and the torque wrench is straight in line with with the locknut tool you have to reduce the setting on the torque to 79 ft lbs

-

1

1

-

-

Is the wire on the Neutral switch? Button ziptied down that is the push to start ??

-

1

1

-

-

Hi: Big Welcome Here

-

1

1

-

-

Check the starter solenoid -- stud going to the starter motor should only have the one large cable on it -- nothing else.

Happy Mothers Day

in General Chat

Posted · Edited by Melatv

To all Mothers -- even those that just have a pet --- Happy Mothers Day