-

Content Count

4,007 -

Joined

-

Last visited

-

Days Won

70

Posts posted by retro

-

-

That's better, it looks like you have a secondary winding now. However, I don't know what the secondary should measure since the service manual doesn't publish that spec. But I expected to see the secondary measuring between 6.5k ohms to 9.8k ohms, within a similar range to the older model coils whose specs were published by Honda. So I don't know.... it looks wrong to me.

Your primary winding measurement is higher than I expected as well, but it looks reasonable, so I can't shoot it down.

My conclusion....? It's possible that your coil is bad but I can't prove my analysis without having a known good working coil in hand to test. I need to understand more about how the ECM loads and unloads the primary winding as well, with the only clue that I have to analyse those functions being that the Black/Red terminal receives battery voltage at all times while the ignition switch is on.

I need a functional Rancher to test and learn from... so basically what I'm saying is that I'm not knowledgeable enough to help you decide whether the ECM (and/or coil) is bad or not.

-

5 hours ago, TBRider said:I thought it was radiant heat. That's why it's cooler in the shade on a hot sunny day....lol

Yes, both the sun and moon are producing radiation within the spectrum of visible light. The radiation from the sun is warm so you escape to the shade for relief from the heat.... While the radiation from the moon is cold so you escape to the shade for relief from the cold. Obviously the moon produces it's own form of light radiation than the sun, which cools the air rather than heats the air. The moon is not a rock just as the sun is not a rock. If the moonlight you observe were indeed reflected radiation from the sun as your rulers would like you to believe, then you would feel and measure warmth from the sun reflected off the moon at night, not cold. In fact, air heated by the sun during the day would remain heated during the night if not for the opposing radiation energy from the moon cooling that air. Energy is required to increase temperature and energy is required to decrease temperature.... lacking an energy force, nothing changes.

-

1

1

-

-

I see no secondary windings at all, the secondary windings are measuring open circuit. Try setting your multimeter to a higher resistance range that will cover up to 10,000 ohms minimum (10k or the next higher range) and measure those again. Make sure that your meter probe is contacting the metal spark plug clip inside the boot while measuring.

-

Nice ride you got there! Congrats!

-

14 hours ago, ATC4ever said:Got real dark & cold all at once.

7 hours ago, jeepwm69 said:Temp here probably dropped 10-15 degrees.

Not trying to start any controversy here, but the moon is a luminary and the sun is a luminary.... and the moon and sun independently produce two distinctly different forms (having differing radiant properties) of light. Neither of them are solid objects, they are both luminaries and neither of them illuminate the other. The sun produces a warm form of light, while the moon produces a cold form of light. Both the sun and the moon luminaries are the exact same size (diameter) as the other -- and both the sun and the moon are local to our closed system we call earth. Ain't neither of them spinning balls hurtling through space, they are part of our local earth system environment.

You can prove to yourself the two distinct light radiation properties generated by the sun and moon. Begin by measuring the air temperature in full sunlight, then measuring air temperature where the sunlight is shaded by a large object (a building, a tree etc.). You'll find that the temperature is warm but is always a bit cooler in the shade where less sunlight is available....

Then measure the air temperature during the night in full moonlight. Next measure the the air temp where the moonlight is shaded by an object (a building, a tree etc.). You'll find that the air temperature is comparatively colder, but is warmer inside the shaded area of moonlight than it is in full moonlight. That stark reality is because the sun and moon are two entirely differing luminaries functioning entirely independent of one another.

Being luminaries, neither the sun nor the moon are solid and neither can be "landed" upon by NASA or SpaceX or anyone else. Space is fake, there is no such thing to access.... space travel is faked and frauded for mind control and revenue robbery purposes. It's just an ordinary govcorp business venture that they began to roll out during 1958, the year after I was born. If you've ever read an encyclopedia published prior to 1958 you already possess this knowledge and much, much more.... Further, if you practice any of the "western" religions then you should already possess knowledge of your stationary local earth and it's closed system which includes the sun, moon, wandering stars (AKA "Plane-ts", haha), the not-wandering (circular motion) stars and the stationary star Polaris at the centermost of earth's system, which marks the location of our north pole.

You also understand that water always finds and maintains it's level and the oceans are perfectly flat. Water does not stick to a spinning ball (incidentally according to the perps -- within a pressurized gaseous atmosphere bordered by a pressure-less "vacuum" of "space") Try that experiment at home.....

Quote

QuoteGenesis 1:16 (KJV)

And God made two great lights; the greater light to rule the day, and the lesser light to rule the night: he made the stars also.

Two lights, not one....

The path of totality of the solar eclipse across the states proves much, much more than you have imagined.... I imagine. If you were paying any attention you know without a doubt that the helio-centric model is childish BS.

-

Our free service manual downloads thread is here:

Welcome to ATVHonda!

-

-

-

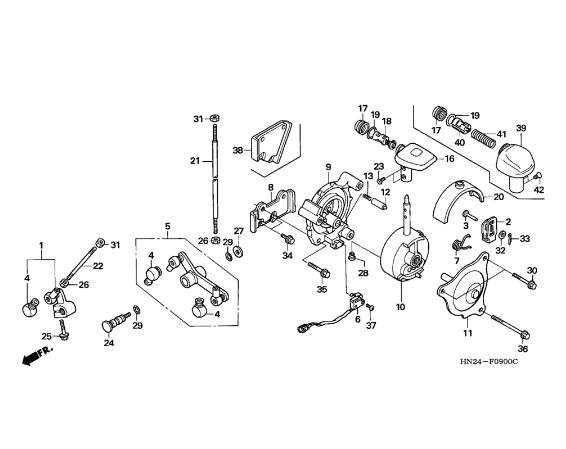

8 hours ago, Davidtorresmx said:Yes, part number 6, Reverse Switch 35370-HN2-005.

https://www.partzilla.com/product/honda/35370-HN2-005

I am only guessing though, I do not know for certain if a bad Reverse switch could cause the motor to die when shifting into gear, or not? This is what I would do....

- Remove the Reverse switch from the gear shifter and try to clean it with electrical parts cleaner solvent or brake parts cleaner solvent, then test it to be sure it works -- then reinstall it onto the gear shifter. If the Reverse switch is bad you'll need to replace it.

- Check the switch on the underside of the Front Brake lever (right side of handlebar) and be sure that the front brake lever returns completely when releasing the front brakes. Does the brake lights work? If the brake lights turn on and turn off properly, then that switch is probably good.

- Unplug and test the Gear Position switch.

- Unplug and test the ESP switch.

- Reinstall all of the genuine OEM Honda parts that you replaced, including the carburetor, if you have not done so yet.

- Finally, you must Initialize the ECM (Initial Setting Procedure) since the Angle sensor and Carburetor were removed and replaced.

I will include test procedures from the service manual in the next post.

Sí, número de pieza 6, interruptor de marcha atrás 35370-HN2-005.

https://www.partzilla.com/product/honda/35370-HN2-005

Sin embargo, solo estoy adivinando, no sé con certeza si un interruptor de marcha atrás defectuoso podría causar que el motor se apague al cambiar de marcha, o no. Esto es lo que yo haría....

- Retire el interruptor de marcha atrás de la palanca de cambios e intente limpiarlo con solvente limpiador de piezas eléctricas o solvente limpiador de piezas de frenos, luego pruébelo para asegurarse de que funcione y luego vuelva a instalarlo en la palanca de cambios. Si el interruptor de marcha atrás está averiado, deberás reemplazarlo.

- Verifique el interruptor en la parte inferior de la palanca del freno delantero (lado derecho del manillar) y asegúrese de que la palanca del freno delantero regrese completamente al soltar los frenos delanteros. ¿Funcionan las luces de freno? Si las luces de freno se encienden y apagan correctamente, entonces ese interruptor probablemente esté en buen estado.

- Desenchufe y pruebe el interruptor de posición de marcha.

- Desenchufe y pruebe el interruptor ESP.

- Vuelva a instalar todas las piezas originales de Honda OEM que reemplazó, incluido el carburador, si aún no lo ha hecho.

- Finalmente, debe inicializar el ECM (procedimiento de configuración inicial) ya que se quitaron y reemplazaron el sensor de ángulo y el carburador.

Incluiré procedimientos de prueba del manual de servicio en la próxima publicación.

-

On 4/5/2024 at 7:52 PM, Davidtorresmx said:Hello, the engine does start, in N it keeps working at idle fine, when changing to D or R the engine turns off immediately, the central screen shows D1, D2 and ESP, but the shutdown problem continues to persist.

@toodeep, do you think a bad gear position switch could cause the ignition to shut down?

-

11 hours ago, jeepwm69 said:This voltage drop......let's say I think it needs a harness...wouldn't using MelATV's little "jumper wire from battery + to the red/black wire on the coil" bypass any burnt/broken wires in the harness by directly supplying 12V to the coil and back feeding 12V to the rest of that circuit IF that were the issue?

Yeah, jumpering battery voltage to the coil would bypass a high resistance joint in the harness. It would do nothing for a shorted wire though.

As you said a harness and an ECU should fix it. Your logic is solid too, swap the harness then the ECU.... it's big bucks and a lot of tedious work but it would be fixed right.

-

I am back home now so I'll read back through this thread later tonight after my work day is done. My intuition is firing off so I might have missed something.

-

This is off-topic but I have an idea that could help us all. Honda stopped including resistance tests in service manuals long ago, so I am thinking about measuring resistance on Ignition coils that I have laying around that are known to be good coils. We could each make a list of resistance tests of coil part numbers that we have on hand and then publish them in a sticky maybe...? @Mach 1 needs those resistance tests right now.

-

1

1

-

-

On 4/1/2024 at 12:04 PM, jeepwm69 said:Both of my splices gave me a tone and showed 0.00 resistance, so that SHOULD mean my splices are good and flowing properly, correct?

As explained above.... maybe, maybe not.

On 4/1/2024 at 12:04 PM, jeepwm69 said:Can I take these apart? I also have continuity between fuse block and the bottom of this little box, with no resistance, so hypothetically, were I to take some of the wires coming out of this box, and do a similar continuity/resistance test would that show an internal problem within this box?

Again maybe, but maybe not. That harness junction could have an overheated pair of wires inside it where they connect together that measures good, but does not pass enough current while under load. Similar to a fuse that overheats the terminals where the fuse plugs in inside a fuse box.... you've seen those failures before.... so you can't rule that possibility out until you get your eyes on the joints in question. I have never tried to open one of those harness junctions so I'm ready to learn what it looks like inside of them, if you are?

All along I have suspected that the ECM is at fault but I've been staying away from that talk because I have no idea how it could be tested.

-

1

1

-

-

On 3/26/2024 at 12:02 PM, jeepwm69 said:So, at this point, I can either buy a new harness, fix this one, or buy a new ECU. I hate throwing money at machines. If I can verify that my splices are ok with a resistance test, I'd lean towards a fried ECU. If my splices are bad, wouldn't they show resistance?

Well, continuity and resistance tests are meaningful only when a wire repair bonds every copper strand inside the wire together and you're 100% sure of that. So for instance, if a broken wire is soldered back together but several of the strands did not get bonded, but two or three strands did get bonded, then that wire repair would test as a good one, but would not necessarily conduct all of the current that the wire (repair) is required to handle during operation under it's normal full current load. In that case the wire would only measure a higher resistance than normal while under load.

That is the reason why @Melatv suggested that you redo the repair that has the all-in-one solder/heat shrink gimmick on it. You can never be sure that the wire strands got hot enough for solder to flow into them to create a bond when using those sort of shortcut gizmos.... the wire conducts heat away quickly along it's length and commonly leaves you with a pretty pool of melted solder --- but a cold solder joint. A good temperature controlled soldering station is a must-have for harness repairs. Weller is one of the best affordable brands...

-

1

1

-

-

Sorry I've been away doing RLS for a while.... If I were you I would measure the resistance of the coil windings of your new OEM coil before going any further. Your coil is getting hot so it might be shorted. So, unplug the coil from the harness and measure resistance between the two connectors. Write that down.... then measure between the Black/Red terminal and ground (the stack of steel plates on the coil) and write that down. Then measure between the Green/Yellow terminal and ground and write that down. Then between the Black/Red and the spark plug boot and between the Green/Yellow and spark plug boot and finally, between the spark plug boot and ground. Let us know those measurements.

-

2 hours ago, jeepwm69 said:Since the CKP test looked ok, safe to say the problem should be in the harness/ECU?

That is my thinking too. In my mind I had narrowed it down to either the JC 2 junction in the harness and/or the ECM. I was trying to stay away from the ECM... don't feel comfortable making those calls on the Internet.

That is a good price for a used harness it's and loaded with parts.

What do you think Mel?

-

It sounds like wiring may be melted together shorting. I'd look for overheating evidence then measure voltages and grounds until the problem is found. Unfortunately I can't help ya sort it out right now since I am well along on a bathroom rebuild project. I'll be gone for another 3 weeks or so.

-

I've never seen a failure inside a harness junction box yet but it's looking like I'm about to. Thanks Mel for jumping in.

-

-

Yeah the coil is marked for each wire color. Do not plug them in wrong, they'll get hot and short.

-

So with the coil plugged in and the Gray ECM connector unplugged there is still a voltage drop measured at the coil Bl/R terminal?

-

11 hours ago, jeepwm69 said:So, while we're on the subject, any "tricks of the trade" for these ancient, rock hard gaskets?

A boiling water bath helps a bit but usually not quite enough... a razor blade scraper is usually what I end up with in my hand.

-

2

2

-

-

That's what I would do.

2010 Honda Rancher 420TEA ignition fuse issue.

in Electronics

Posted

That sounds reasonable to me! DO NOT PLUG THE NEW COIL IN THOUGH! Just measure it when you get it and let us know those readings so we can analyze them. Mark the new coil that you have now and mark the new coil when it arrives so you won't get them mixed up while we test them. In the meantime I am going to try to build a Peak Voltage Adapter for you.